| SPECIFIC SYSTEM SYSTEM OPTIMISED BY DIATEX |

|

|

Vacuum Moulding or Vacuum Bagging Composites

Vacuum moulding of composite materials involves using a number of vacuum consumables that have an effect on the production and quality.

Some of these are used in successive layers, such as peel ply, perforated film, breather felt, and vacuum-bagging film.

Standard procedures involve applying each one separately (e.g., peel ply, perforated film, breather felt), which can be difficult,

especially when moulding is done against a vertical mould

Diatex has designed a specific range of bagging materials for prepregs and hand lay-up composite materials with vacuum polymerisation.

The success of Diatex is based on the manufacture of innovating products, such as Vacuopeel, Vacuoplex MP and Vacuolease,

whose purpose is to facilitate the application of environmental products by users during drape moulding operations.

Diatex also offers all standard environmental products as well as the equipment which is used in this manufacture process in compliance with our quality system.

Diatex R&D department : working towards innovation. From the manufacture of technical textiles to the design of vacuum systems,

Diatex has developed its research activities by recruiting specialists and reinvesting a significant percentage of its turnover into the implementation of new processes.

|

|

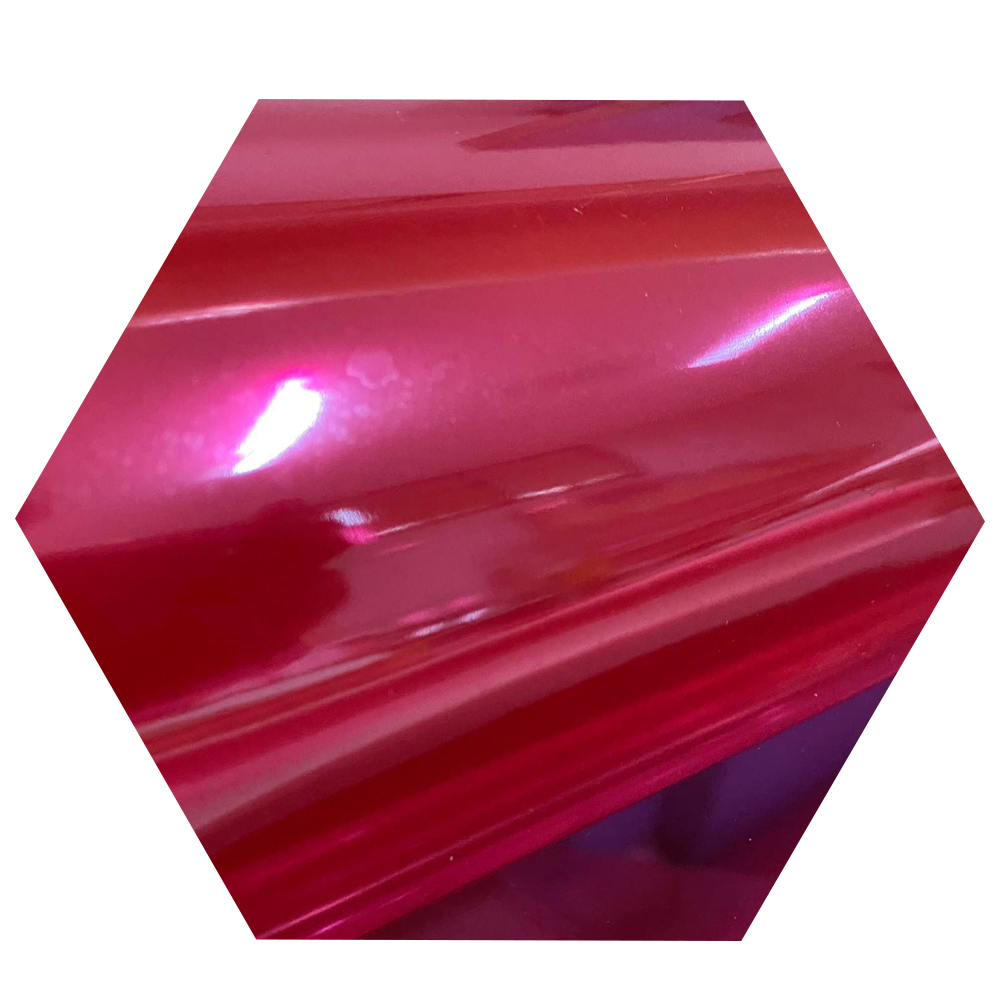

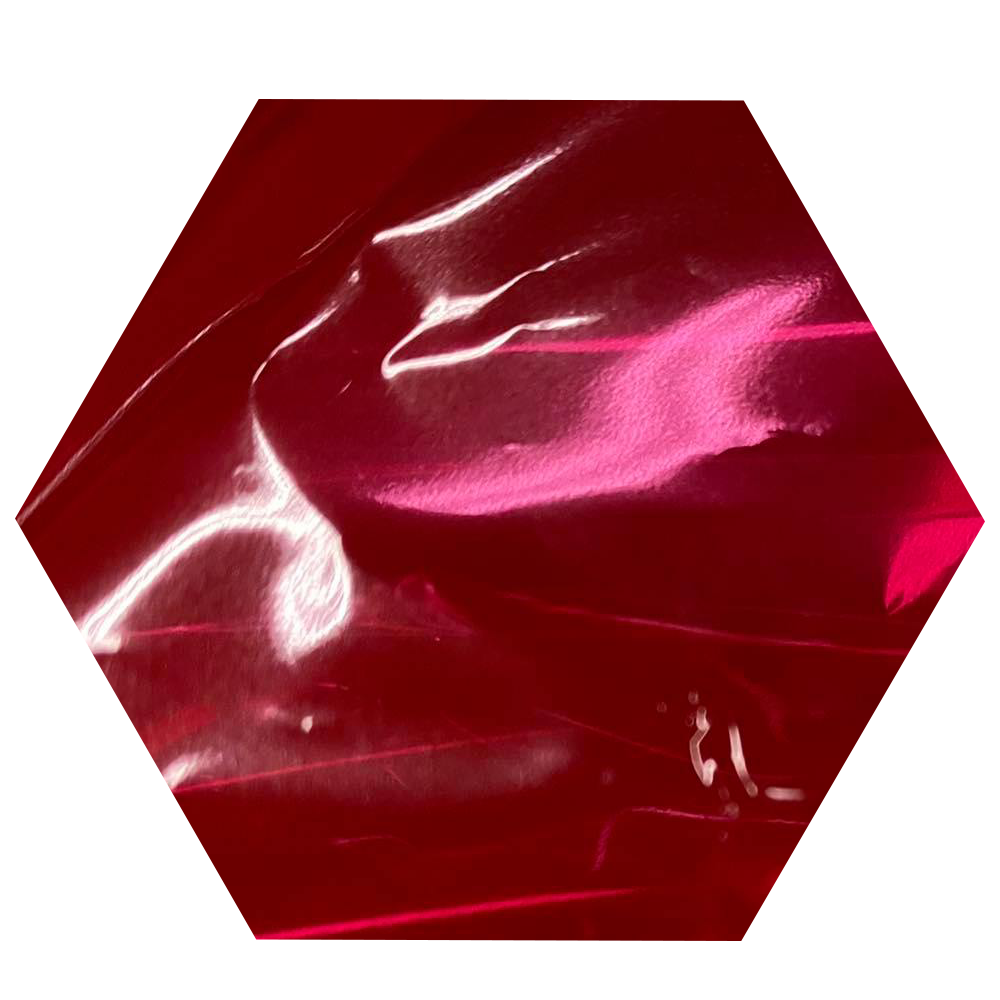

NEO SHEET

|

Bagging film are recommended for moulding of elaborate forms for protection air pass between inside and outside of mould. Bagging film are recommended for moulding of elaborate forms for protection air pass between inside and outside of mould.

Advantages are good machanical and chemical resistance, important elonggation rate, non porous, cost effective.

Neosheet 60 micron PE+Nylon+PE Local

packing

width : 1.88 meter

length : 100 meter per roll

temperature resistance : 120 C

Download specification

|

|

BF 120

|

BF 120 Thickness 65 micron Nylon+PP+Nylon China BF 120 Thickness 65 micron Nylon+PP+Nylon China

width : 4.00meter and 6 meter

length : 100 meter per roll

temperature resistance : 150 C

Download specification

|

|

PO 180

|

Bagging film PO180 : Diatex France Download specification Bagging film PO180 : Diatex France Download specification

Packing : width 2400 mm x 100 m

PO180 is an advances nylon copolymer film. PO180 is a multilayer extruded nylon film providing multilayers of safty.

PO180 is strong, has a high elongation and is suitable for cure temperatures up to 180 C.

PO 180 The new nylon bagging film Ref. PO180 limits waste. Used for vacuum moulding, 50 micron of

PO180 is equivalent to 75 micron traditional film. It is available in lay-flat tubing and sheet.

PO180 is suitable with polyester and epoxy resins, its composition based on polyamide and

polypropylene provides good mechanical and chemical properties.

|

|

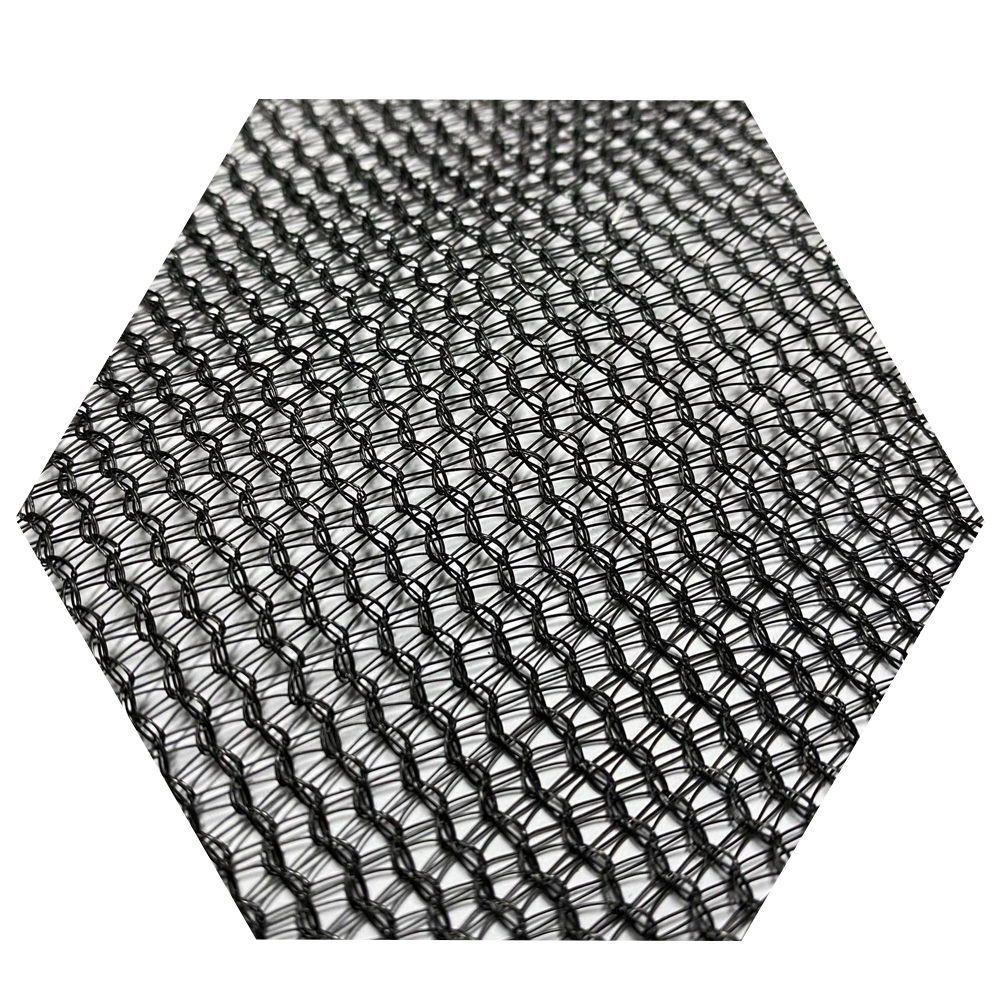

FMK 120P-2000

|

FMK 120E-2000 120 g/m2 PE Knit China : flexible breather for curve part FMK 120E-2000 120 g/m2 PE Knit China : flexible breather for curve part

Packing

Black color

width : 2.0 meter

length : 100 meter per roll

temperature risistance : 120 C

Download specification

|

|

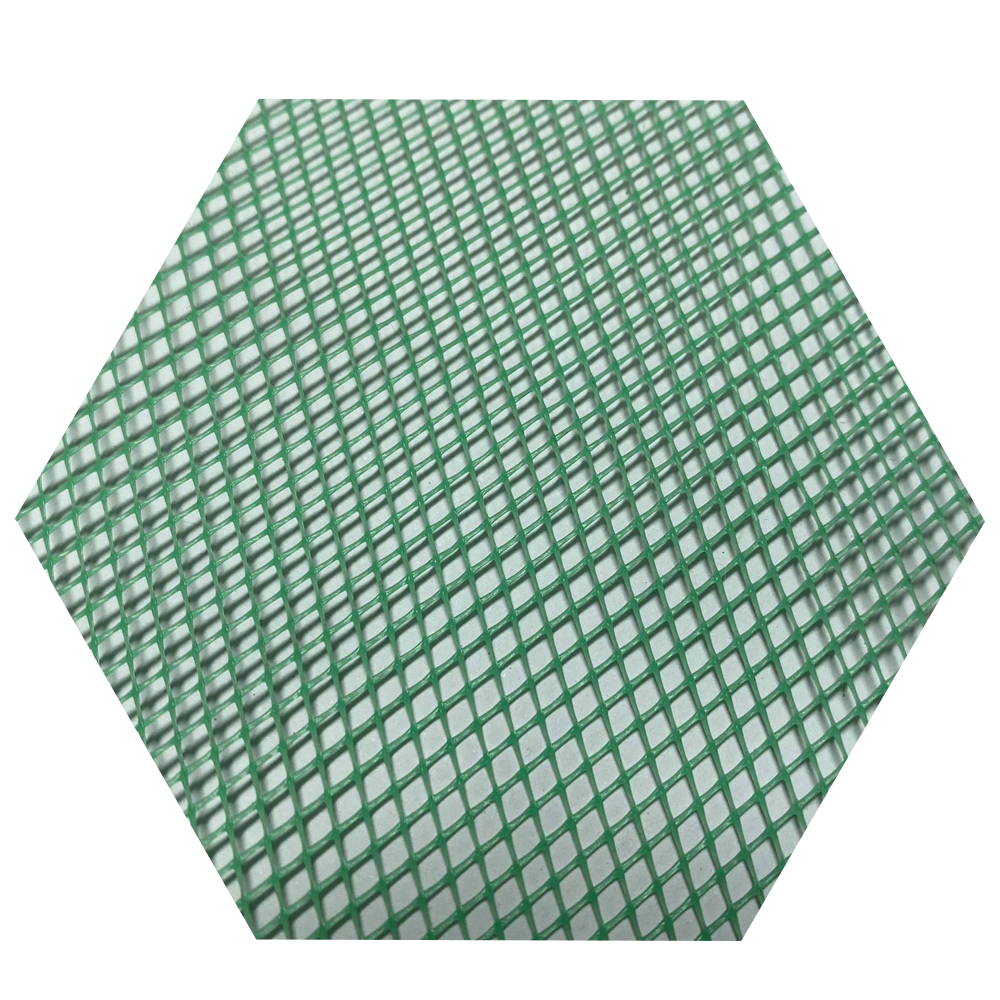

FMK 100E-1200

|

Flow Media Net Breather are recommended for the polyester or epoxy infusion with vacuum process. Flow Media Net Breather are recommended for the polyester or epoxy infusion with vacuum process.

The porosity of those net bleeders is calibrated.

FMK 100P-1200 120 g/m2 PE Knit China : Good resin flow for flat surface panel

Packing : Green color width1.20 meter x length 100 meter per roll, temperature resistance 120 C

Download specification

|

|

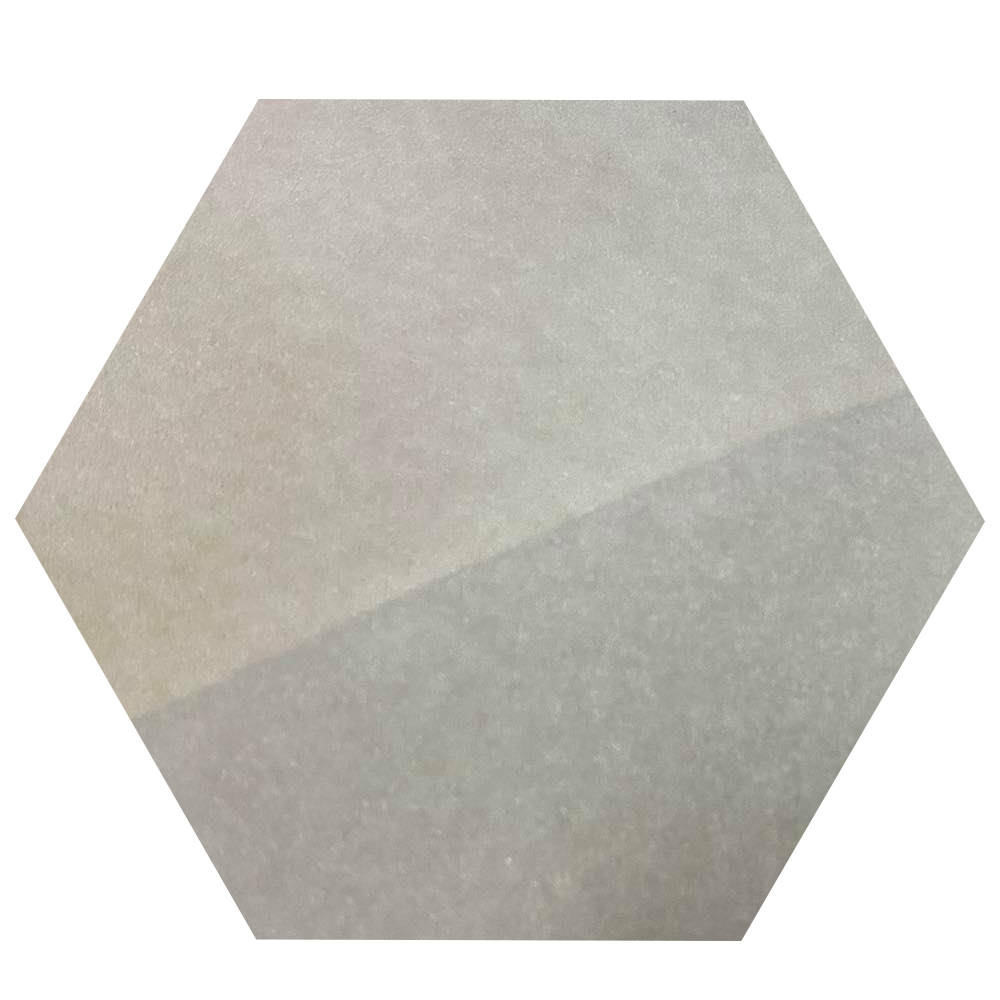

PB 150

|

Breather Non woven breather made of polyester fibres. There is recommented for the moulding of elaborate forms Breather Non woven breather made of polyester fibres. There is recommented for the moulding of elaborate forms

PB 150 150g/m2 China Packing : width 1.50 meter x length 100 meter per roll

|

|

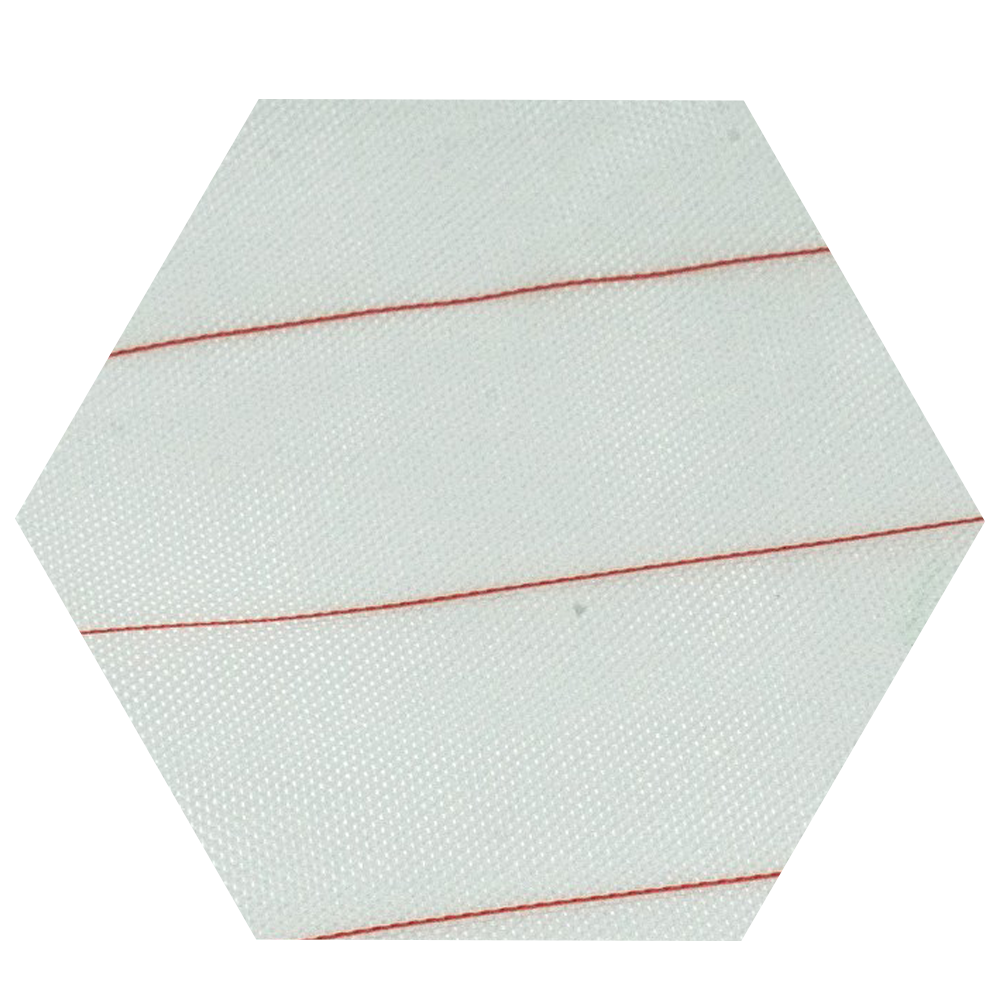

Peel ply

|

Peel ply Those fabrics are used to impart a textured surface to the moulded component to Peel ply Those fabrics are used to impart a textured surface to the moulded component to

improve adhesion in secondary boning or painting.

PA 66-85 RS 80 g/m2 white with red stripe Nylon 66 China Packing : width 1.50meter x length 100 meter per roll

Download specification

PA 80 80 g/m2 white with red and green sytrip Nylon 66 Packing : width 1.61m,eter x length 100 meter per roll

|

|

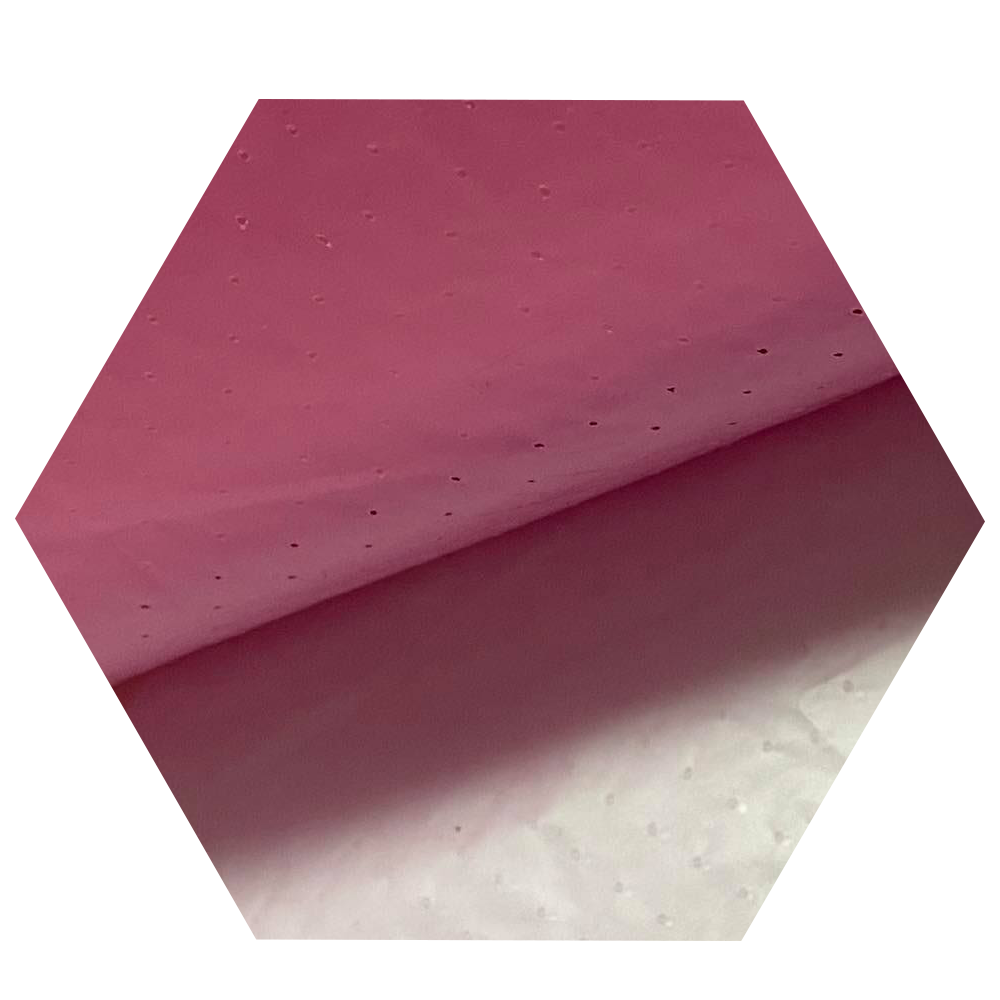

PDF 120 -1350 mm

|

Perforated Film are films have a good chemical and thermal resistance for release films with a large range of resins. Perforated Film are films have a good chemical and thermal resistance for release films with a large range of resins.

PRF 120-1350 P1 RED 20 micron red CoPolymer PE Packing : width 1.35 meter x length 400 meter per roll ,

temperature resistance 120 C, thickness 35 micron

Download specification

|

|

SF-PP-35 Non-Perforated Film - 1500 mm

|

SF-PP-35 Non-Perforated Film - 1500 mm width 1.35 meter x length 400 meter ,temperature resistance 120 C, thickness 35 micron SF-PP-35 Non-Perforated Film - 1500 mm width 1.35 meter x length 400 meter ,temperature resistance 120 C, thickness 35 micron

Download specification

|

|

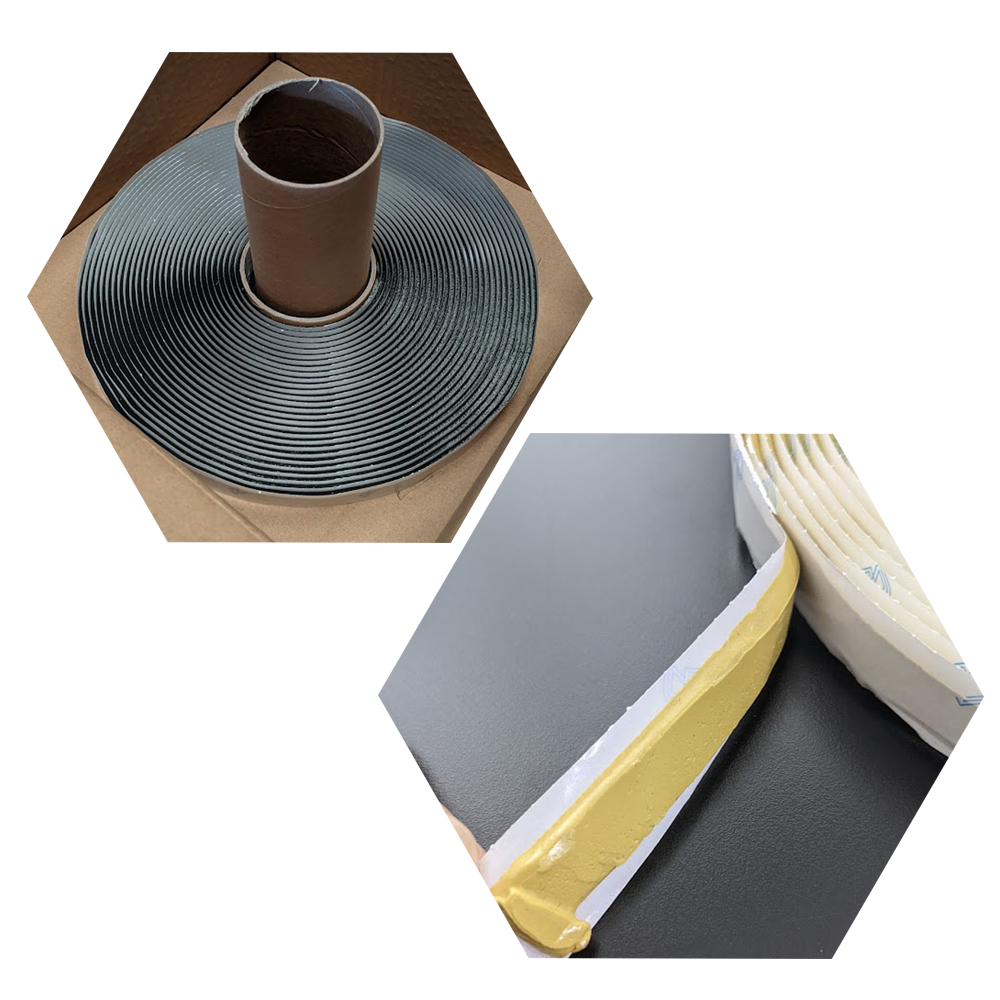

Sealant tape

|

Sealant tape are used to from a seal between the vacuum bagging film and the moulding tool surface. Sealant tape are used to from a seal between the vacuum bagging film and the moulding tool surface.

Sealant tapes compatible with most bagging films.

ST 150 Chaina Black 230 C Packing : thickness 3 mm x width 12mm length 15 meters per roll, 10 rolls per carton

|

|

Resin Profile

|

Omaga Profile resin flow channel employed and prepreg processes Omaga Profile resin flow channel employed and prepreg processes

OE 18 Lintex China White Packing length1 meter per peice

|

|

Flat Flow Media DIADRAIN

|

Flat Flow Media DIADRAIN is a flat resin or vacuum channel.It consists of a three-dimentional Flat Flow Media DIADRAIN is a flat resin or vacuum channel.It consists of a three-dimentional

polyester filament core structure wrapped in a non woven polyester sleeve.

Color white, Max service 80 C thickness 4 mm width 50 mm weight 35 g/m leangth 100 meter

Download catalog

|

|

PE Tube

|

PE Tube feeding channe; for resin in vacuum infussion, LRTM and prepreg process PE Tube feeding channe; for resin in vacuum infussion, LRTM and prepreg process

E10 Polyethylene 10 mm ID Packing : Length 100 meter per roll

E12 Polyethylene 12 mm ID Packing : Length 100 meter per roll

|

|

PE Spiral Warp

|

PE Spiral Warp flow channel for resin in vacuum infusion and prepreg process PE Spiral Warp flow channel for resin in vacuum infusion and prepreg process

Packing Length 100 meter per roll

|

|

Vacuum pump

|

Vacuum pump Vacuum pump

The automatic vacuum pumps, are perfectly adapted for to composite industry : vacuum moulding, vacuum infusion and RTM

Description motor vacuum pump 3/4 hp tank air size 35 liters with vacuum gage and digital electronic control valve and lighting show

status of working and setting pressure unit in 6 types KPa, Mpa, Kgs/CM3, Bar, PSI, mmHg, inHg and inlet open-close valve in roller

wheel for comfortable moving

Download specification :

|

|

Catchpot

|

Catchpot : resin trap for vacuum infusion and LRTM process Catchpot : resin trap for vacuum infusion and LRTM process

Application:To trap resin excess to vacuum pump in standless steel container with glass view lid and a inlet connection for pipe

ID 10 mm and a connection with valve control for vacuum pump and vacuum pressure gage,

Packing container resin size 1 lit and 2 lits and 20 lits capacity of packing 1 set

|

|

T connector

|

T connector : T connector :

TCL 10 Brass : OD 10 mm local packing 20 peices per bag

TC10 Plastic China : OD 10 mm and 12 mm packing 10 peices per bag

TC10 Plastic Diatex France : OD 10 mm packing 25 peices per bag

|

|

Valve Tap

|

Valve Tap Valve Tap

IV 10 with red valve grip Lintex China OD 10 mm 10 peices per bag

V 10 with black valve grip Diatex France OD 10 mm 10 peices per bag

|

|

INFUTAC High Strength Moulding Spray Adhesive

|

INFUTAC High Strength Moulding Spray Adhesive INFUTAC High Strength Moulding Spray Adhesive

INFUTAC is an infusion adhesive specifically designed to hold reinforcing fibers in place.

Used for Infusion. vacuum moulding or RTM.

Safety Fuses Laminating Materials to Structural Core Surfaces

Provides Superior Holding During Forming Process

Allows Resin to Obtain Maximun Tensile Sheer Strength

Low Shrinkage in Curing

Fine Mist Adhesive with green tracer for accuracy in application

Fast Tack

HAPS Free

Packaging : Aerosol 610 ml - 425 g Download catalog

|

|

Infusion box

|

Infusion box Fixing the resin flow tube and connecting omega profile or spiral tube. Mainly used in vacuum Infusion box Fixing the resin flow tube and connecting omega profile or spiral tube. Mainly used in vacuum

infusion and prepreg process.

Packing 10 peices per box

|

|

Vacuum plug, Vacuum regulator, Vacuum Valve

|

Vacuum plug, Vacuum regulator, Vacuum Valve Vacuum plug, Vacuum regulator, Vacuum Valve

Vacuum plug system adapted to the vacuum moulding technology. The new vacuum plug help to save time and avoid leakage problems.

New Vacuum Plug advantages:

-Auto Perforating System (there is no need to perforate the bagging film upstream)

-Unblocking System (the operculum made by the perforation will not block the vacuum and there is no need to remove it)

In order to avoid the pressure losses on the vacuum level, it is imperative to use the adapted interior diameters of pipe

|

|

Wing seal Black neoprene

|

Wing seal Black neoprene Code : RD476-003 Diatex France Wing seal Black neoprene Code : RD476-003 Diatex France

Wing seal for use as vaccum seal where rim of flanges mould to hold vacuum pressure of flange. The seal is black neoprene

Packing : 25 meter per roll

|

|

Standard Dynamic Seal White

|

Standard Dynamic Seal White Code : RD421-001Diatex France Standard Dynamic Seal White Code : RD421-001Diatex France

Dynamic seal for use as a resin seal in RTM or Light RTM moulds, to reduce seal drag when closing the mould

where flanges are too steep for conventional seals. The seal inflated or collapsed under vacuum using seal.

Control unit possibility to do the vacuum inside thanks to the installation kit CO-RD20-2056

Packing : 25 meter per roll

|

Vacuum Bagging Bagging film, Peel ply, sealant tape etc